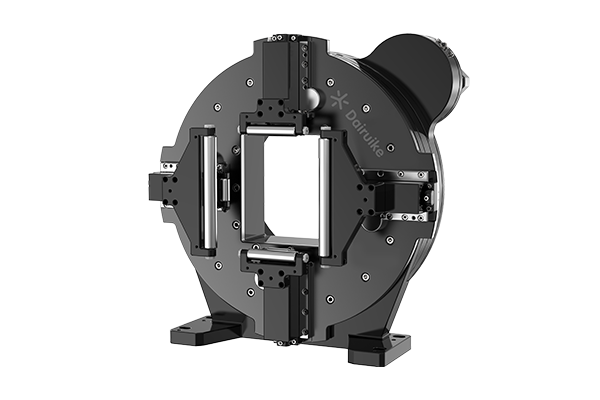

Square pneumatic chuck 240JS for laser cutting machine

▎Description

DRK-240JS pneumatic chuck upgrades the design of square hole and through hole, all square and round can be used to realize the processing of various types of materials and special-shaped pipes. The square hole pneumatic chuck is independently developed by Dai Ruike. It is higher and can fully meet the cutting needs in different scenarios.

- 240JS square pneumatic chuck is a general-purpose chuck worthy of selection. It adopts a square through-hole structure design. The diameter of the front cartoon hole reaches 242mm. It can process pipes with a diameter range of Φ10-220mm, At the same time, it also breaks through the limitation that the round hole chuck cannot clamp the square tube to the maximum. The 240JS pneumatic chuck can clamp the square tube of 220mm at the maximum.

- In order to ensure the clamping accuracy, the clamping transmission mechanism of the 240JS pneumatic chuck has good sealing performance, which effectively prevents the failure of the transmission mechanism caused by the entry of dust and other debris. At the same time, the transmission efficiency and synchronization accuracy have also been greatly improved, ensuring clamping accuracy and stability.

- The design of 240JS square pneumatic chuck is very simple and flexible. It adopts one-piece casting and stable reducer installation, which makes users more worry-free during installation and debugging. The pneumatic chuck can be selected from multiple angles, and the adjustment of the stop guide is also very convenient, so that the user can complete the adjustment more quickly. At the same time, the clamping force of the chuck is very large, and the load-bearing capacity is stronger, which can easily clamp pipes of various shapes. The standard channel steel jaws can clamp large profiles, making the clamping process more stable. The two clamps can clamp pipes up to 260kg to meet various processing needs of users.

In short, the 240JS pneumatic chuck breaks through the limitation of the round hole chuck, has the advantages of the largest processing diameter of the square tube, high clamping accuracy, good stability, superior protection effect, convenient and flexible use, and is a general-purpose type worth recommending. The chuck will provide users with a more efficient and accurate solution for pipe processing.

▎Why should the pneumatic chuck front chuck with round holes be upgraded to square holes?

1.Increase the clamping size range: the square hole pneumatic chuck front chuck adopts the central through hole as a square hole. Compared with the traditional round hole chuck, the square hole design can increase the clamping size of the square tube specification, thereby expanding the scope of use and adapting to more processing needs.

2.Adapt to clamping of various materials: the length of the rollers of the square hole pneumatic chuck front chuck is long, which can meet the clamping requirements of various materials with special shapes such as angle steel, channel steel and H-shaped steel. This design improves the flexibility and adaptability of the chuck, which can meet the processing needs of different materials.

3.Self-contained pressure-holding function: The square hole pneumatic chuck front chuck clamp has its own pressure-holding function, which can provide continuous pressure-holding effect during the clamping process, ensuring clamping stability and processing quality. Long-term pressure-holding capabilities help increase productivity and process consistency.

4.Convenient maintenance and cleaning: the dust cover of the pneumatic chuck front chuck is a split design, which is easy to disassemble and clean. This allows for easy maintenance and maintenance of the chuck, prolongs its service life and ensures consistent performance.

5.Dust-proof design and air-tightness optimization: The internal slider of the square hole pneumatic chuck front chuck has a dust-proof ring, which effectively prevents dust from entering the sliding parts and reduces the occurrence of friction and jamming.

6.Quality inspection before leaving the factory: The square hole pneumatic chuck front chuck has undergone strict quality inspection before leaving the factory, including air tightness inspection, action test run and precision inspection, etc. This ensures that the chucks meet high quality and precision requirements before being delivered to the customer.

▎Precautions for pneumatic chuck:

- If the user observes the rules of product transportation, storage, equipment, adjustment, maintenance and use, if he finds that the product cannot work normally due to manufacturing quality problems, or finds that the packaging quality is poor and the product is damaged when unpacking, the accessories do not match the packing list , or insufficient parts, etc., please contact our company’s quality department within one month after receiving the goods. When sending information, please indicate the model, specification, serial number and delivery date of the product.

2.The product should be installed and used in an environment of 0-40°C.

3.When using product equipment, users must strictly abide by the specifications. If you have any questions or suggestions for improvement, please notify the after-sales department.

▎Performance Parameter

| OD mm |

Spindle Bore mm |

Centre-height mm |

Total Weight kg |

Inertia Kg.cm2 |

Repeatability mm |

Rotary precision mm |

| Φ685 | Φ242×242 | 350±0.05 | 240 | 73000 | ≤0.05 | ≤0.05 |

| Single Claw trip mm |

Single Claw thrust Kg.f |

Processing Range mm |

Permissible pressure Mpa |

Rated speed rpm |

thickness of pipe mm |

Holdup time h |

| 120 | 240 | 10-230 | 0.3-0.8 | 150 | ≥1 | 12 |

▎Application

The application of Pneumatic chuck in the hardware processing industry has the following advantages:

Shorten the processing cycle: Pneumatic chuck can effectively shorten the processing and manufacturing cycle of new products. Compared with traditional processing methods, laser cutting does not need to make molds, which saves the time and cost of mold development. This enables enterprises to respond to market demands faster and improve production efficiency.

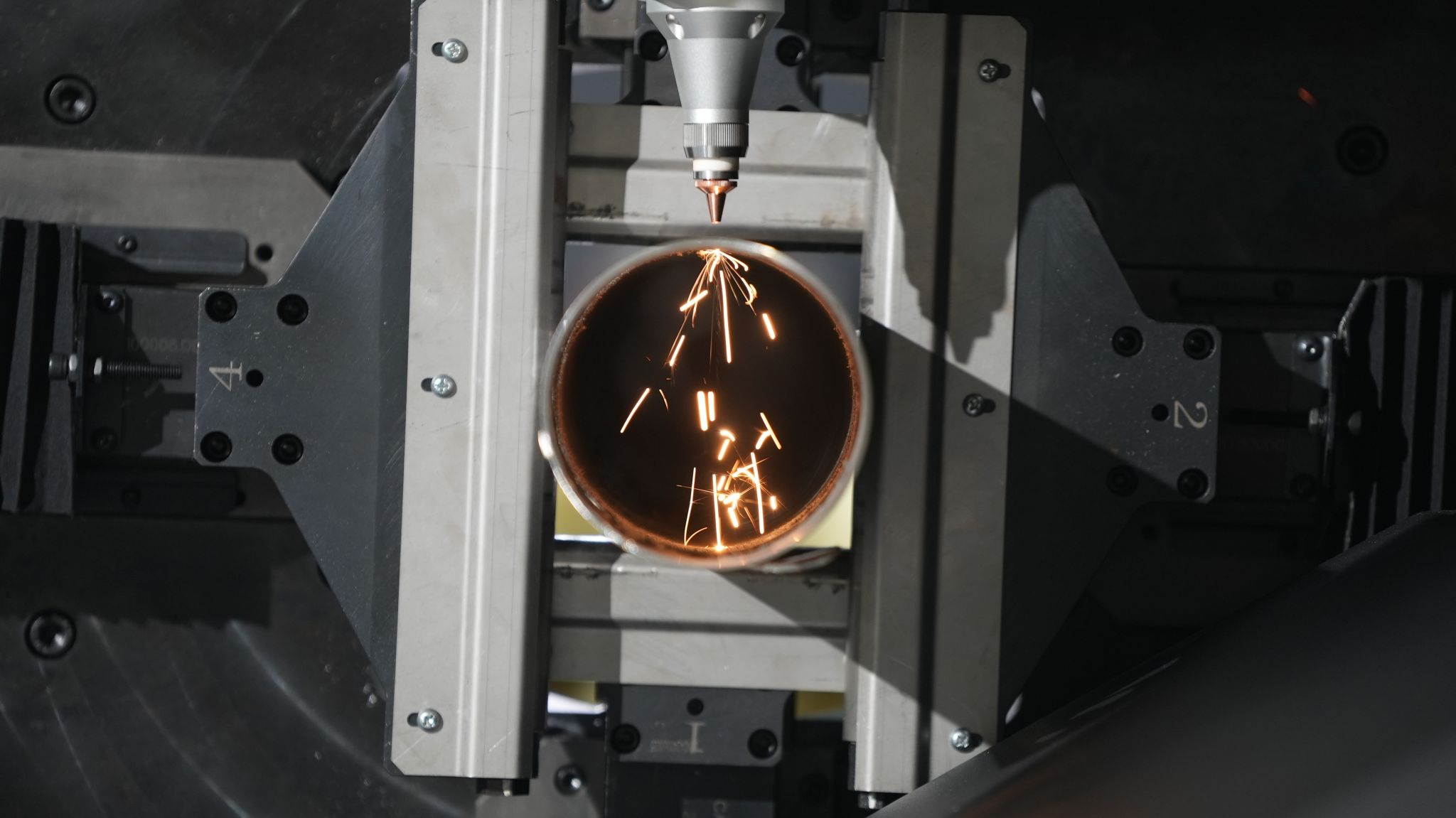

Processing complex parts: Pneumatic chucks can effectively process various complex parts in metal processing. Through laser cutting technology, the precise processing of non-standard parts such as special-shaped pipe fittings can be realized, avoiding the limitations of traditional processing methods. This improves machining accuracy and precision and shortens the machining cycle.

Improve processing efficiency: The wide application of Pneumatic chuck can improve the processing efficiency of workers. Compared with traditional processing methods, laser cutting does not require manual clamping and feeding, and has a high degree of automation, reducing human input and unnecessary processing procedures. This helps businesses improve production efficiency and product delivery speed.

Tailor-made and on-demand processing: Pneumatic chucks can develop related products according to customer needs, and realize tailor-made and on-demand processing. There are many special-shaped pipe fittings in the hardware industry that cannot be processed by traditional pipe cutting machines, and laser chucks can solve these problems and meet the processing needs of customers’ specific requirements.

In short, the application of Pneumatic chuck in the hardware processing industry can shorten the processing cycle, improve processing efficiency, process complex parts, and realize tailor-made and on-demand processing. These advantages help enterprises improve production efficiency, reduce costs, and at the same time meet the market’s demand for high-precision and personalized products. The application of Pneumatic chuck has promoted the development and innovation of the metal processing industry.