▎Description

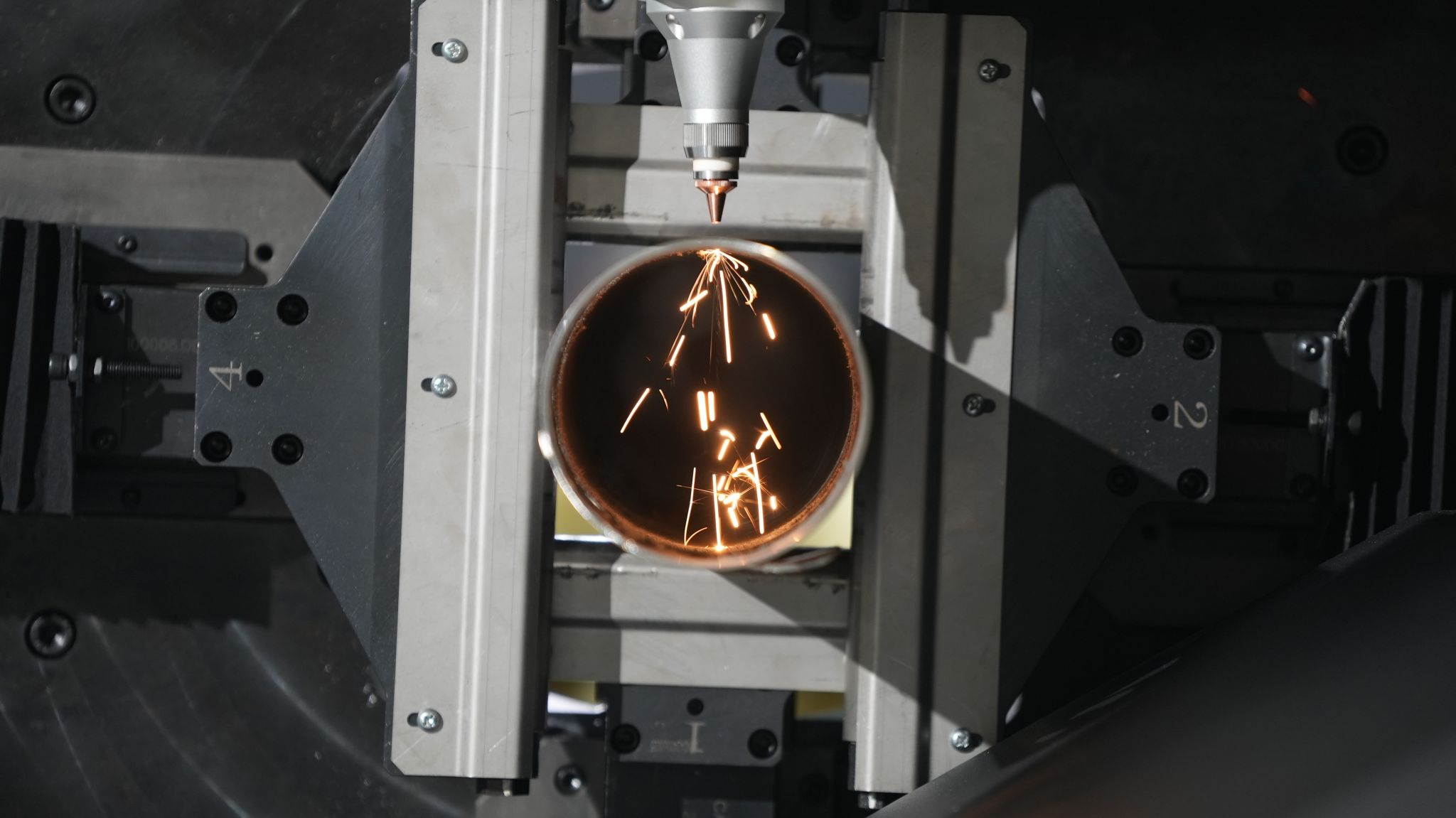

DRK-120 laser rotary chuck is born for small laser pipe cutting

In order to meet the high-speed, high-efficiency and high-performance cutting requirements of metal pipe production enterprises for small pipes, Dairuike 120 laser rotary chuck is known as an artifact for small pipe processing. For the comprehensive working conditions processing scene of small pipes, it has great potential for the comprehensive working conditions processing scene of small pipes, which can effectively improve the production speed, improve the cutting quality, and expand the production capacity.

- The DaiRuiKe laser rotary chuck is a specialized component designed for laser pipe cutting machines. Its compact structure and high dynamic performance make it an ideal choice for precision cutting applications. The laser rotary chuck is designed and matched specifically for small laser pipe cutting, ensuring optimal performance and efficiency. With its dual advantages of small laser pipe cutting effect and efficiency, the DaiRuiKe laser rotary chuck is an essential tool for any laser pipe cutting operation.

- This laser rotary chuck is specially designed for small pipe cutting, and its biggest feature is fast! The body of the laser rotary chuck is made of aviation aluminum, which has good characteristics such as smoothness, non-stick oil, anti-oxidation, and high appearance.

- The cutting acceleration of the DRK-120 laser rotary chuck reaches 1.5G, which realizes ultra-fast cutting and satisfies the user’s clamping of various profiles, while improving the processing efficiency of the whole machine by 35%, exceeding expectations.

- This laser rotary chuck does not need to adjust the claws for clamping pipes within the full stroke range. It has stable clamping force and accurate clamping. It adopts double roller claws. When the pipe processing meets the precision, it is convenient to prevent the pipe from being thrown when the laser rotary chuck rotates at a high speed.

- This laser rotary chuck has less residual material, which improves the utilization rate of the pipe. The rear chuck extends the front chuck to the maximum, shortens the distance between the cutting head and the rear chuck jaws, and the length of the tail material is ≤49mm.

- Such a high-speed, high-precision, stable and reliable, material-saving laser pipe cuttingmachine chuck makes small laser pipe cutting easier

If you mainly use small pipes, you can choose this laser rotary chuck. 120 laser rotary chuck is widely used in metal furniture, medical equipment, office supplies, display cabinets and other industries. In the future, Dairuike laser rotary chuck will continue to develop and evolve, bringing laser clamping experience with excellent clamping and stronger performance to metal manufacturing enterprises.

▎Why choose Dairuike laser rotary chuck?

1.Tailor-made solutions

Our team of experienced and professional engineers can provide customized and exclusive solutions to meet the specific needs of customers. According to our customers’ product requirements, we provide laser rotary chuck solutions that exceed their expectations.

2. Excellent after-sales support:

Our online after-sales engineers are committed to providing one-on-one technical service guidance. We are committed to ensuring a hassle-free experience for our customers, promptly assisting and resolving any technical issues that may arise during the purchase and use of our laser chucks.

3.Free training service:

DaiRuike provides free training service conducted by our technical engineers. Whether it is the installation of laser chucks, safety precautions, or training on the use of cutting specifications, we provide remote and comprehensive training to ensure that customers can operate the equipment with confidence.

▎FAQ

Q: Value and quality?

A: Don’t just pursue cheap prices while ignoring product quality. Make sure to choose a high-quality laser rotary chuck for precise and stable cutting. You get what you pay for, and investing in quality chucks can lead to better results and long-term benefits.

Q: The importance of after-sales service?

A: The convenience and reliability of after-sales service are factors that need to be considered when choosing a chuck. Failure to obtain after-sales support in the event of a chuck failure can lead to production interruptions and losses. Choosing a perfect after-sales service system can better guarantee the continuity and efficiency of production.

Q: The importance of on-site inspection?

A: For more expensive lasers, it is recommended to visit the supplier’s factory site in person. On-site inspection can more intuitively understand the scale, professionalism and production capacity of the manufacturer, and on-site testing can also be carried out to verify the performance of the machine. Ultimately, purchase decisions are made based on budget and comprehensive metrics.

▎Performance parameter

| OD mm |

Spindle Bore mm |

Centre-height mm |

Total Weight kg |

Inertia Kg.cm2 |

Repeatability mm |

Rotary precision mm |

| Φ430 | Φ130 | 235±0.05 | 92 | 10200 | ≤0.05 | ≤0.05 |

| Single Claw trip mm |

Single Claw thrust Kg.f |

Processing Range mm |

Permissible pressure Mpa |

Rated speed rpm |

thickness of pipe mm |

Holdup time h |

| 63 | 80 | 10-120 | 0.3-0.8 | 150 | ≥1 | 12 |

▎Application