▎Description

The pain points in small pipe processing

- Complex Processes: Traditional small tube processing involves multiple steps such as loading and unloading, angle cutting, hole punching, drilling, and more. It can require up to nine different operations, making the process complex and inefficient. The application of the 120JL laser chuck for small tubes is becoming a key solution to address these issues.

- Difficulty in Processing Small Tube Sizes: Small pipe materials come in various sizes with small diameters and wall thicknesses typically ranging from 0.5mm to 1.5mm. Their low rigidity makes them susceptible to deformation under external forces, such as bending, twisting, or warping. The stable clamping force of the 120JL laser chuck effectively prevents material deformation and damage caused by physical pressure, ensuring material integrity and quality.

- Insufficient Machining Precision: Traditional machining methods struggle to maintain overall precision for tube materials. Whether it’s a sawing machine, punching machine, or drilling machine, there are machining errors, and these errors accumulate with each operation. Human intervention is often required, and human errors can add to the final product’s inaccuracy, compromising product quality. The 120JL laser chuck, Standard double roller design, offers high precision and reduces human operational errors, ensuring higher product quality.

- Low Processing Efficiency: Traditional machining equipment like sawing machines, punching machines, and drilling machines are inefficient when processing small tube materials. They require frequent positioning and adjustments, lacking efficiency and precision control. In the furniture industry, for example, the variety of hole types in tube connections presents challenges for traditional equipment, which may require additional costs to develop different molds. The application of laser chucks reduces the reliance on manual labor due to their high automation and precision control, significantly reducing labor costs and human errors.

- High Labor Costs: Due to the low level of automation in traditional equipment, almost every step of the operation relies on manual intervention, from feeding to positioning, processing, and material retrieval. With increasing labor turnover and wage demands, labor costs have become a significant pressure point for businesses.

In summary, by introducing laser chucks, the small tube processing industry can address multiple issues encountered in traditional small tube material processing. This includes optimizing the processing workflow, improving precision, and reducing costs, ultimately enhancing overall production efficiency and product quality.

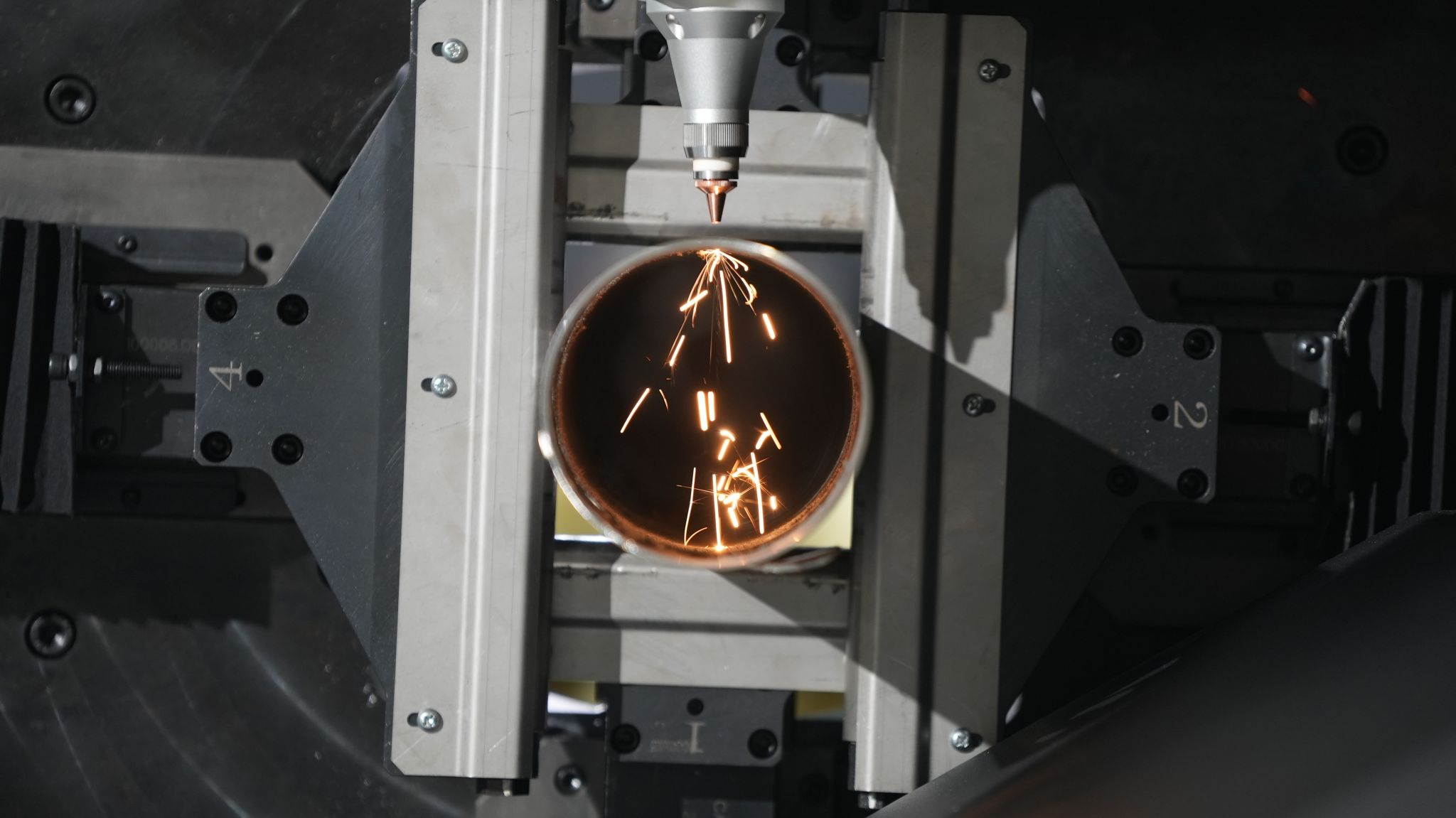

Friends who need to process small tubes need not worry. This is a laser chuck specially designed for small tube cutting. It can cut any tube with a diameter of 10–120 mm. With a variety of complex cutting processes, the square-hole laser chuck is designed to process various types of tubes.

Laser chuck has the following characteristics:

1. Quick!

It has a small moment of inertia, the laser chuck can adapt to high-speed operation, and it has high processing efficiency.

High-speed cutting in large quantities, with acceleration up to 1.5G

2. High precision:

cutting accuracy can be controlled within 0.05mm

3. High equipment configuration:

The laser chuck gear is fully sealed, which not only prevents debris from entering during processing but also affects the processing accuracy.

It also reduces the hours of manual maintenance and greatly saves labor costs.

4. Supports clamping of small tubes and special-shaped pipes

Round tubes φ10~φ125mm, 10×10-120x120mm square pipes, I-beam/channel steel: Maximum No. 8

5. The single claw thrust force is large and the load-bearing capacity is further improved

The diameter of the through hole is expanded to 130 x 130 mm, the types of small tube clamping are increased, and the load-bearing capacity is increased by 50%

6. When cutting a single pipe, the entire pipe can be cut with a single clamp, and the cutting length is not limited by the length of moving parts

7. High-cost performance and easy to operate!

Known for its compact design and high precision, this chuck is perfectly adapted to the processing needs of small-diameter pipes. Its efficient cutting capabilities make it the tool of choice for processing small tubes, especially in fine crafts. The DRK-120’s stable clamping and rapid rotation ensure continuity and precision in the cutting process, making it an ideal companion for small tube processing.

With the rear chuck and two-clamp clamping, it truly realizes automated pipe processing. The rear chuck adopts a special barrel design. The two-clamp clamped pipe provides excellent support strength and stability while maintaining light operability. It can efficiently handle all types of small and thin-walled pipes, achieving precise and rapid processing.

The DRK-120 is not only suitable for fiber laser cutting machines, but its versatility allows it to clamp a variety of pipes, including round, rectangular, and special-shaped pipes. Its lightweight construction and durable internals make it a tool built to last. The chuck’s closed-back design and automatic air blow feature reduce maintenance requirements while increasing productivity.

The DRK-120 laser chuck has excellent performance in material utilization and reduces waste, especially in the cutting tail. Its design greatly shortens the distance between the cutting head and the claw, improving material utilization efficiency.

To sum up, the DRK-120 laser chuck is an efficient tool specially designed for small pipe processing and is suitable for a variety of industries. Dai Ruike is committed to providing customers with more effective solutions through this innovative product to meet their needs. Evolving needs while driving the company’s continued development and innovation.

▎Performance parameter

| OD (mm) |

Centre-height (mm) |

Total Weight (Kg) |

Inertia (K g.cm ²) |

Repeatability (mm) |

Rotary precision (mm) |

| Φ238 | 125±0.05 | 60.5 | 2600 | ≤0.10 | ≤0.15 |

| Single Claw trip (mm) |

Single Claw thrust (Kg.f) |

Processing Range (mm) |

Permissible pressure (M pa) |

Rated speed (rpm) |

thickness of pipe (mm) |

| 25 | 78 | 10-120 | 0.3-0.8 | 150 | ≥1 |

▎Application

For a small tube-cutting laser chuck, Dai Ruike’s requirements are:

Not just precision, but high precision

Not just fast, but super fast

Not only quality but also high-quality

Not only do we need to save money, but we also need to save big and special based on high precision, ultra-fast speed, and high quality!

It is specially designed for the rapid cutting of large quantities of small metal pipes in metal furniture, office furniture, electric vehicles, bicycles, medical equipment, fitness equipment, agricultural machinery, municipal guardrails, advertising decoration, and other industries.