Introduction

Pneumatic chuck front chucks have become an integral part of modern industries, revolutionizing the way various manufacturing processes are carried out. These innovative solutions offer exceptional gripping power and versatility, providing a secure hold on workpieces during machining, turning, and other precision operations. In this article, we will explore the significant role of pneumatic chuck front chucks in modern industries and delve into the various ways they contribute to efficiency, accuracy, and productivity.

Understanding Pneumatic Chuck Front Chucks

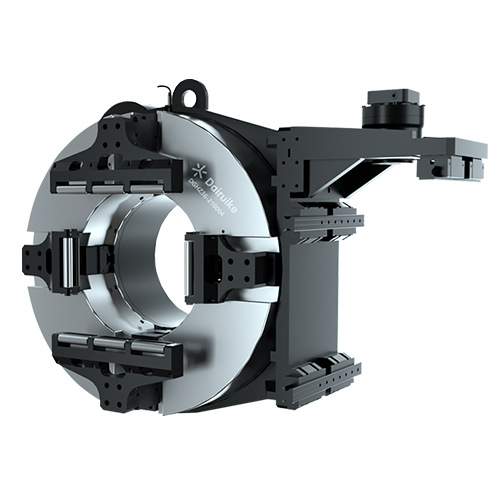

To comprehend the role of pneumatic front chucks, let’s start by understanding their fundamental characteristics. A pneumatic front chuck is a specialized clamping mechanism designed to hold and secure workpieces during machining or turning operations. It utilizes compressed air to create a powerful gripping force, ensuring stability and precision throughout the manufacturing process.

Versatile Workpiece Clamping

One of the key advantages of pneumatic chuck front chucks is their versatility in workpiece clamping. These chucks can securely hold a wide range of workpiece shapes, sizes, and materials. Whether it’s cylindrical, irregular, or asymmetrical workpieces, pneumatic front chucks provide a reliable and adaptable clamping solution. This versatility eliminates the need for multiple clamping devices, streamlining production and reducing setup times.

Enhanced Precision and Accuracy

Precision and accuracy are paramount in modern industries, and pneumatic chuck front chucks excel in delivering consistent results. With their robust gripping force and stability, these chucks ensure minimal workpiece movement during machining or turning processes. This reduces vibrations, eliminates chatter, and enhances the precision of cuts, resulting in superior surface finishes and tighter tolerances. Manufacturers can rely on pneumatic front chucks to achieve the desired quality and accuracy in their finished products.

Quick and Efficient Workpiece Changes

In fast-paced manufacturing environments, the ability to change workpieces quickly and efficiently is crucial. Pneumatic chuck front chucks offer rapid workpiece changeovers, minimizing downtime and maximizing productivity. With their user-friendly design and simple operation, operators can release the current workpiece, insert a new one, and securely clamp it in a matter of seconds. This seamless transition enables manufacturers to maintain a smooth workflow, meeting demanding production schedules with ease.

Increased Operator Safety

Safety is a paramount concern in any industrial setting, and pneumatic front chucks prioritize operator well-being. These chucks incorporate advanced safety features, such as built-in sensors and interlocks, to prevent accidental release of workpieces during machining or turning. Additionally, the powerful gripping force of pneumatic chuck front chucks ensures workpiece stability, reducing the risk of workpiece ejection or movement that could cause injuries. Operators can work with confidence, knowing that their safety is prioritized.

Automation Integration for Efficiency

Automation has transformed the manufacturing landscape, and pneumatic front chucks seamlessly integrate with automated systems. These chucks can be incorporated into CNC machines and robotic cells, allowing for unmanned or lights-out production. The compatibility with automation enables continuous operation, reduces human intervention, and optimizes production efficiency. Pneumatic chuck front chucks play a vital role in modern industries by supporting the transition towards smart factories and Industry 4.0.

Conclusion

Pneumatic front chucks have redefined workpiece clamping in modern industries, providing enhanced precision, versatility, and efficiency. Their ability to securely grip a wide range of workpieces, deliver consistent accuracy, facilitate quick changeovers, and prioritize operator safety makes them indispensable in machining and turning operations. As industries continue to evolve and embrace automation, pneumatic chuck front chucks will play a vital role in driving productivity and maintaining a competitive edge. Manufacturers can rely on these chucks to meet the demands of fast-paced production environments while ensuring the highest standards of quality and precision.

With their versatile clamping capabilities, pneumatic chuck front chucks can accommodate a wide range of workpiece shapes, sizes, and materials. Whether it’s cylindrical, irregular, or asymmetrical workpieces, these chucks provide a secure and reliable grip. This versatility eliminates the need for specialized clamping devices, streamlining production processes and reducing setup times.

The precision and accuracy offered by pneumatic chuck front chucks are essential for achieving desired machining or turning results. The powerful gripping force and stability of these chucks minimize workpiece movement, reducing vibrations and eliminating chatter. This results in superior surface finishes and tight tolerances, meeting the stringent requirements of modern industries. Manufacturers can rely on pneumatic front chucks to consistently produce high-quality components and products.

In fast-paced manufacturing environments, time is of the essence. Pneumatic front chucks enable quick and efficient workpiece changes, minimizing downtime and maximizing productivity. Operators can release the current workpiece, insert a new one, and securely clamp it within seconds, allowing for seamless transitions between different machining or turning operations. This efficiency ensures a smooth workflow and enables manufacturers to meet tight production schedules.

Operator safety is a top priority in industrial settings, and pneumatic chuck front chucks incorporate advanced safety features to protect workers. Built-in sensors and interlocks prevent accidental release of workpieces during machining, reducing the risk of injuries. Additionally, the powerful gripping force of these chucks ensures workpiece stability, minimizing the chances of workpiece ejection or movement that could pose hazards. Operators can work with confidence, knowing that their safety is taken into account.

The integration of pneumatic chuck front chucks with automation systems is another significant advantage. These chucks can seamlessly work with CNC machines and robotic cells, facilitating unmanned or lights-out production. By reducing the need for human intervention, manufacturers can achieve continuous operation, optimize production efficiency, and embrace the concept of smart factories and Industry 4.0. Pneumatic front chucks play a pivotal role in enabling the transition towards advanced automated manufacturing processes.

In conclusion, pneumatic front chucks have a vital role in modern industries. Their versatility, precision, quick workpiece changes, operator safety, and integration with automation systems contribute to efficient and productive manufacturing operations. By harnessing the power of pneumatic chuck front chucks, manufacturers can achieve consistent quality, meet demanding production requirements, and stay ahead in today’s competitive industrial landscape.

Related Products