Application field of laser pipe cutting machine:

A laser pipe cutting machine is an advanced cutting equipment with many applications. In modern manufacturing, laser pipe chuck machines are widely used to process objects such as metals, non-metallic materials, and pipes. Its main applications include the following aspects:

First, Pneumatic Chuck play an essential role in metal processing. Whether in automobile manufacturing, shipbuilding, or aircraft manufacturing industries, Pneumatic Chucks are widely used in cutting metal pipes, such as stainless steel, aluminum alloy, copper, etc. Laser cutting technology can realize high-precision and high-efficiency cutting processes, which ensures the precision and quality of processed parts.

Secondly, the application of pneumatic chucks in construction is also very important. In the building decoration industry, metal pipes of various shapes are often clamped, such as round, square, oval, etc., and the precise clamping helps the laser pipe cutting machine to complete the complex cutting process.

Used in petrochemical, aerospace and other fields. In the production process of petroleum and chemical pipelines, pneumatic chucks can quickly clamp pipelines of different diameters and materials, ensuring the accuracy and stability of cutting and processing. Help enterprises realize efficient pipe processing, improve production efficiency and ensure product quality.

Pneumatic Chuck play a vital role in many industries. Its high-precision, high-efficiency, and flexible features enable it to meet the cutting needs of various materials and shapes. With the continuous progress and innovation of technology, Confident the application field of Pneumatic Chuck will be further expanded to provide greater convenience and benefits for the processing and manufacturing of all walks of life.

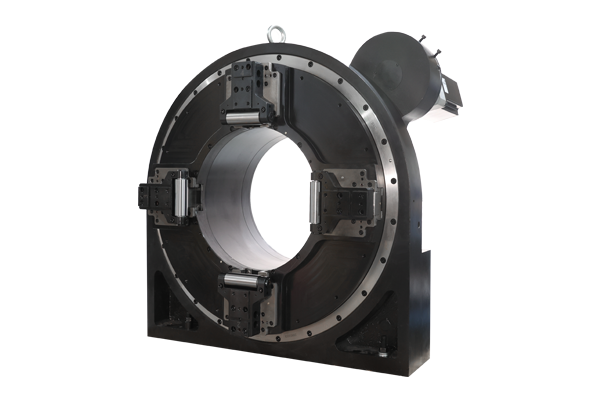

Pneumatic Chuck structure:

The chuck structure of a laser pipe chuck machine generally includes a chuck body, inner core, and chuck jaws. The chuck body is a circular structure made of aluminum alloy, cast iron, etc., with good wear resistance and durability. The inner core is a hollow structure that can drive the opening and closing of the chuck claws through the air cylinder or oil cylinders. The chuck jaws are the main components for clamping the pipe, generally made of hard aluminum alloy or steel, durable and strong in tensile strength. The design of the entire chuck structure is reasonable, which can better meet the processing requirements of different pipes to ensure cutting accuracy.

Maintenance precautions for Pneumatic Chuck:

The Pneumatic Chuck , which has the advantages of fast processing speed and high cutting precision and is deeply loved by customers in various industries. If we want the laser tube cutting equipment to be used for a long time and improve the efficiency of cattle production, then we need to do an excellent job in daily maintenance during use.

- Make sure the gas used is clean and stable compressed air. The air pressure is controlled within the range of 0.4~00.9MPa. Selecting a gas pipe with a pressure greater than 1.6MPa to connect to the product. At the same time, make sure that the gas pipe is far away from heat sources and open flames; otherwise, it will affect the use and bring hidden dangers to production.

- Before use, the operator should carefully check whether the fastening screws of the jaws are fastened and whether the air source pressure is normal.

- Use a high-pressure air gun or similar tools to clean the chuck body and slideway surface and wash away the layer of dust, which can ensure the accuracy of the chuck of the laser pipe machine.

- Apply molybdenum disulfide grease (black ) at least once a day, and inject the grease into the nozzle until the grease overflows the jaw surface or the inner hole of the chuck.

- When the Pneumatic Chuck is not used for a long time, the workpiece cannot be clamped on it to prevent the deformation of the chuck from affecting the accuracy;

- Metal is easy to oxidize and rust because the rust of the chuck of the laser pipe cutting machine will reduce the clamping force, failing to clamp the workpiece and causing work errors, so the anti-rust effect cutting oil is generally used to provide the chuck with anti-rust comprehensively. It can prevent the internal rust of the chuck because the rust of the chuck will reduce the clamping force, and the workpiece cannot be clamped.

The above content concerns the precautions for maintaining. While doing the above 6 points, we also need to clean the active parts 2-3 times a week, and the chuck should be cleaned every two months. Maintenance and checking whether each component is damaged or broken; if the wear is serious, it must be replaced in time.

The rear chuck of this Pneumatic Chuck is high rigidity, and the chuck is intimately equipped with an air-blowing function, which can effectively remove dust and residues in the jaws during the cutting process, which solves the worries for customers and is convenient for operation and maintenance. The internal structure is precise, the wear resistance is good, the structure is compact, and the floor space is small.

Furthermore, we take pride in our commitment to customer satisfaction. We offer comprehensive training and support services to ensure that our customers can maximize the benefits of our Pneumatic Chuck. Our dedicated team of experts is available to provide technical assistance, answer questions, and offer guidance throughout the entire process.