Introduction to Fiber Laser Cutting

Fiber laser cutting is a process that involves using a high-powered laser to cut materials accurately. The laser beam is directed onto the material, and the heat generated melts or vaporizes the material, creating a precise cut. This technique is commonly used in the manufacturing industry to cut a variety of materials, including metal, plastic, and wood.

Compared to other cutting methods, fiber laser cutting offers several advantages. Firstly, it is incredibly accurate, allowing for precise cuts that are difficult to achieve with other methods. Secondly, fiber laser cutting is fast and efficient, making it ideal for high-volume production. Finally, it is a cost-effective method since it requires minimal maintenance and produces less waste.

Importance of Precision Cutting in Manufacturing

Precision cutting is essential in the manufacturing industry since it affects the quality of the final product. To achieve the desired level of precision, it is crucial to use the right equipment. Even minor errors in cutting can lead to significant defects in the final product, which can be costly to correct.

By using a fiber laser cutter front chuck, manufacturers can achieve a high level of precision, reducing the risk of defects and minimizing waste. This is particularly important when working with expensive materials, such as metals, where even a small error can result in significant losses.

What is a Fiber Laser Cutter Front Chuck?

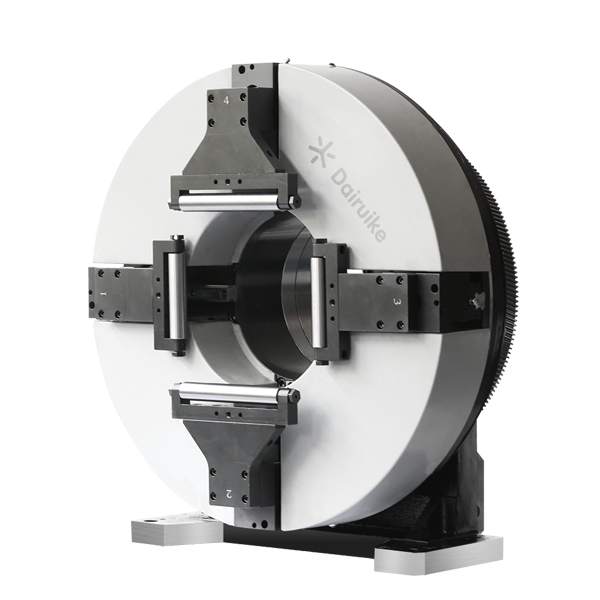

A fiber laser cutter front chuck is an accessory that is attached to the front of a fiber laser cutter. It is designed to hold the material firmly in place during the cutting process, ensuring that it remains in the correct position and angle. This is important since even minor movement during cutting can affect the accuracy of the cut.

Fiber laser cutter front chuck come in different sizes and shapes, depending on the type of material being cut. They are typically made of high-quality materials, such as stainless steel or aluminum, to ensure durability and longevity.

Benefits of Using a Fiber Laser Cutter Front Chuck

Using a front chuck in fiber laser cutting offers several benefits. Firstly, it ensures that the material remains in the correct position, minimizing the risk of movement during cutting. This results in a more accurate cut, reducing the risk of defects and waste.

Secondly, a fiber laser cutter front chuck allows for more precise cutting angles, enabling manufacturers to create complex shapes and designs. This is particularly important when working with intricate designs or small parts, where precision is crucial.

Finally, using a front chuck improves the overall efficiency of the cutting process. By holding the material firmly in place, it reduces the need for manual adjustments or repositioning, saving time and reducing the risk of errors.

Types of Fiber Laser Cutter Front Chuck Available in the Market

There are several types of front chucks available in the market, each designed for specific applications. The most common types include:

- Pneumatic chucks: These use compressed air to hold the material in place, making them ideal for lightweight materials.

- Hydraulic chucks: These use hydraulic pressure to hold the material in place, making them suitable for heavy-duty cutting applications.

- Mechanical chucks: These use a mechanical locking mechanism to hold the material in place, making them ideal for high-precision cutting.

Choosing the right type of fiber laser cutter front chuck depends on the specific requirements of the cutting application. Factors such as the type of material, thickness, and shape of the material should be considered when selecting the appropriate front chuck.

Factors to Consider When Choosing a Fiber Laser Cutter Front Chuck

When choosing a front chuck for your fiber laser cutter, several factors should be considered. These include:

- Material compatibility: Ensure that the front chuck is compatible with the type of material being cut.

- Chuck size: Choose a front chuck that is the right size for your laser cutter to ensure a proper fit.

- Chuck capacity: Consider the maximum weight and size of the material that the front chuck can hold.

- Accuracy: Choose a front chuck that offers high levels of accuracy to ensure precise cuts.

- Durability: Ensure that the front chuck is made of high-quality materials to ensure longevity and durability.

Maintenance and Care of Fiber Laser Cutter Front Chuck

To ensure optimal performance and longevity of the front chuck, proper maintenance and care are essential. Regular cleaning and lubrication should be carried out to prevent rust and corrosion. The chuck should also be inspected regularly for signs of wear and tear, and any damaged parts should be replaced promptly.

Comparing Fiber Laser Cutter Front Chuck with Other Laser Cutting Techniques

While front chucks are commonly used in fiber laser cutting, other laser cutting techniques are available. These include:

- CO2 laser cutting: This method uses a high-powered CO2 laser to cut materials. It is often used for cutting thicker materials.

- Plasma cutting: This method uses a plasma torch to cut materials. It is often used for cutting metal.

Compared to these methods, fiber laser cutting offers several advantages, including higher levels of accuracy, faster cutting speeds, and lower operating costs.

Testimonials from Businesses that Have Implemented Front Chucks in Their Fiber Laser Cutting Process

Many businesses have reported significant improvements in their fiber laser cutting process after implementing front chucks. These include:

- Improved accuracy and precision, resulting in higher-quality products.

- Increased efficiency and productivity due to reduced waste and fewer errors.

- Reduced operating costs due to lower maintenance requirements and less material waste.

Conclusion

In conclusion, using a fiber laser cutter front chuck offers several benefits, including higher levels of accuracy, improved efficiency, and reduced waste. When choosing a fiber laser cutter front chuck, it is essential to consider factors such as material compatibility, chuck size, and accuracy. With proper maintenance and care, a front chuck can provide long-lasting and reliable performance, improving the overall quality and productivity of the cutting process.

Related Products