▎Description

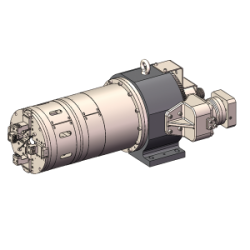

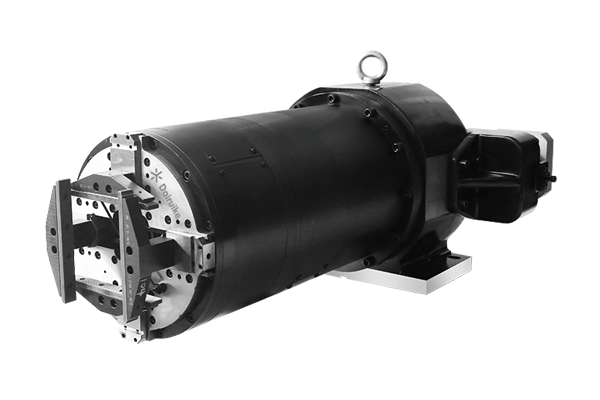

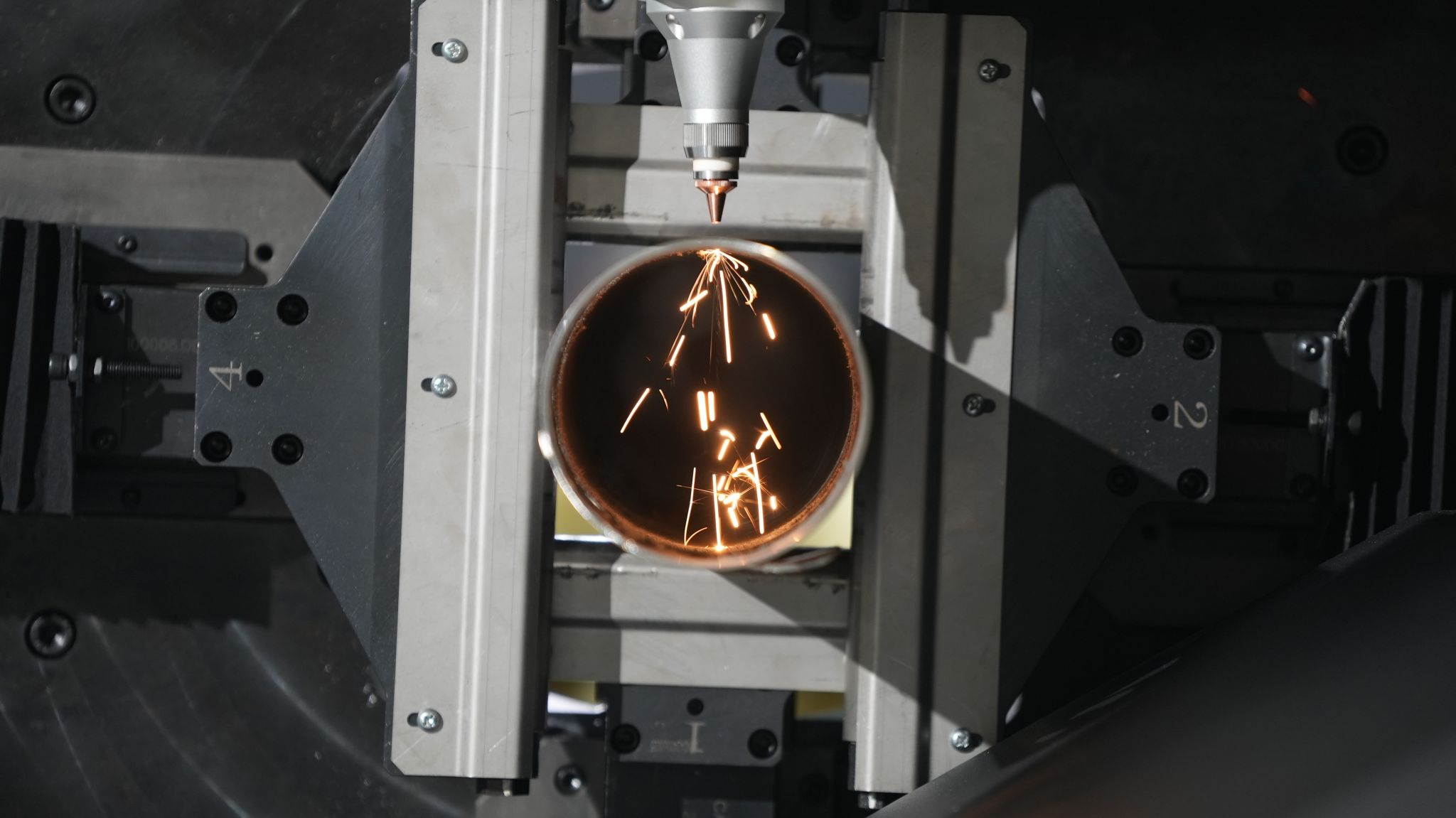

An indispensable component of the laser pipe cutting machine – the laser rotary chuck. When the laser pipe cutting machine is cutting and processing pipe fittings, it is necessary to clamp and fix the pipe fittings with a chuck to ensure stable and accurate cutting.

- The rear jaws of the 280JL rotary chuck are made of steel, and the surface has been specially treated, which has excellent properties such as high temperature resistance, wear resistance, and corrosion resistance. Its clamping method usually uses four jaws to clamp the pipe fittings, and the cooperative clamping of the front and rear clamps can keep the workpiece balanced and stable.

- The characteristics of the rear rotary chuck of the DRK-280JL rotary chuck are as follows:

New barrel design: With a new barrel design, the clamping stroke is larger, the types of jaws are less, the operation is more convenient, and efficient pipe processing can be realized.

- Standard reducer base: DRK-280JL laser rotary chuck rear chuck is equipped with a reducer base as standard, which can install the reducer more flexibly and improve processing efficiency and precision.

- Stability of support and load: The integral support seat structure of the rear chuck enhances the stability of support and load, which can ensure the accuracy and stability of the processing process.

- High precision: high transmission efficiency and synchronization precision, which can realize precise positioning and clamping of workpieces, and improve machining accuracy and efficiency.

- DRK-280JL rotary chuck rear chuck is an efficient, stable and precise auxiliary equipment for pipe fittings processing, which can provide a stable rear chuck support for laser cutting and ensure the stability and precision of the workpiece during processing. Widely used in metal processing, industrial manufacturing and other fields, it is one of the important equipment to improve production efficiency and product quality.

This Rear chuck is a supporting equipment for the laser cutting machine that can clamp and feed the tube when cutting the pipe. It can clamp various specifications of round pipes, rectangular pipes, channel steels, I-beams, angle steels, special-shaped pipes, etc., taking into account all materials.

▎Misconceptions about price

What price misunderstandings will occur when choosing a rotary chuck

At this stage, many enterprises are facing problems such as high labor costs, low production efficiency, and serious waste of raw materials. Therefore, some manufacturing enterprises at this stage have begun to explore new production and processing methods to change the current production and management problems. The emergence of fiber laser chucks has solved these problems very well. With strong processing capabilities, fiber laser chucks have now been widely used in all walks of life. So what price misunderstandings will we face when choosing laser cutting equipment? How to distinguish?

1. Understand the functions of the fiber rotary chuck price endowed to the product

People have higher and higher requirements for fiber laser chucks, and subconsciously think that the price should also be higher and higher. With this kind of price misleading, many people are price-oriented when choosing laser cutting equipment; while ignoring the quality, practicability and function of the product.

2. Understand the misunderstanding of the price of laser rotary chuck

There are many price misunderstandings when buying fiber laser chucks, which will lead to the price of pipe rotary chucks. Check whether the qualifications of fiber laser chuck manufacturers are really qualified and whether the production scale is large enough. If the fiber laser chuck does not choose a good manufacturer, it will not only affect the price of the fiber laser chuck, but also affect the business process when it is actually used. The operation will be very inconvenient, resulting in endless waiting and maintenance.

3. About the safety of laser rotary chuck price

If the price of laser cutting equipment is too low, there may be certain safety hazards. Inferior fiber optic fiber rotary chuck products may cause some failures during use and fail to meet the use requirements. As a result, the low-priced fiber rotary chuck may have some problems that affect the user experience during the working process.

▎Performance parameters

| OD (mm) |

Centre-height (mm) |

Total Weight (kg) |

Inertia (Kg.cm²) |

Repeatability (mm) |

Rotary precision (mm) |

| Φ349 | 182.5±0.05 | 185 | 13800 | ≤0.1 | ≤0.15 |

| Single Claw trip (mm) |

Single Claw thrust (Kg.f) |

Processing Range (mm) |

Permissible pressure (Mpa) |

Rated speed (rpm) |

thickness of pipe (mm) |

| 50 | 490 | 10-280 | 0.3-0.8 | 150 | ≥2 |

▎Application