▎Description

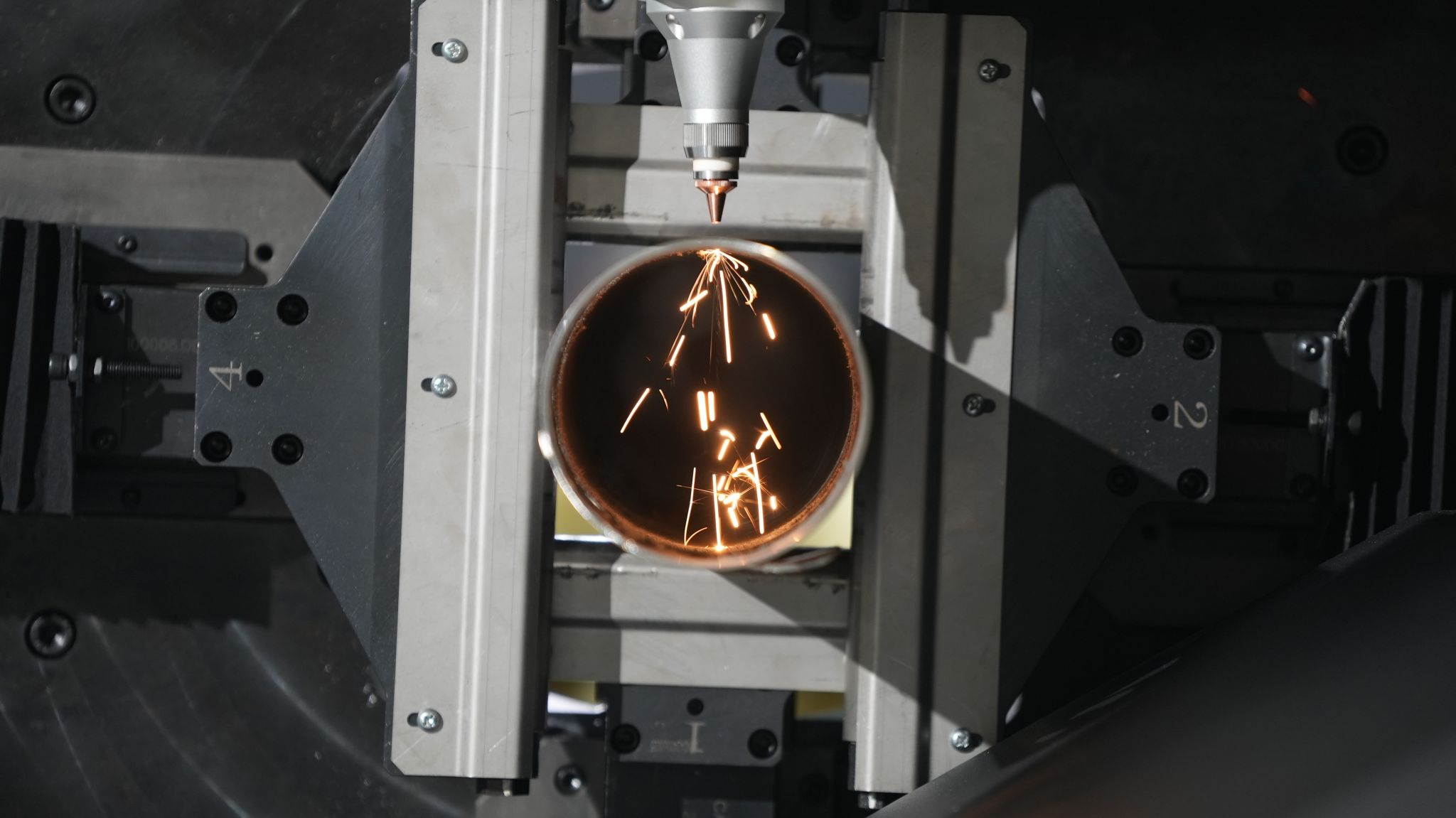

Dairuike 220B pneumatic rotary chuck has many advantages and characteristics, which is one of the important factors for users to choose this product. Let’s introduce the characteristics and advantages of the back chuck in detail.

- Using keyway positioning, no need for comb adjustment

The rear jaws of Dairuike 220B pneumatic rotary chuck adopt keyway positioning design, which makes the pipe clamping more stable and reliable. Compared with traditional comb positioning, keyway positioning does not require cumbersome comb debugging, which greatly saves debugging time and improves production efficiency.

- Easy maintenance, built-in gears to prevent cutting dust from entering

The design of the Dairuike 220B pneumatic rotary chuck rear chuck is very simple and easy to maintain and maintain. Its gear built-in design can prevent cutting dust from entering the inside of the gear, thereby reducing the maintenance frequency of the chuck and prolonging its service life.

- One-piece casting design, stable installation of reducer

The integrated design of the installation of Dairuike 220B pneumatic rotary chuck rear chuck reducer greatly saves the customer’s production and debugging costs, and also increases the stability of the product. The one-piece casting design can not only improve the installation accuracy of the reducer, but also effectively avoid loosening during installation, making the chuck more stable.

- Less residual material, high material utilization rate

The rear chuck of Dairuike 220B pneumatic rotary chuck can extend out of the front chuck, which greatly reduces the waste of tailings, high material utilization rate, and effectively reduces the production cost of the enterprise.

In a word, the front chuck matched with the Dairuike 220B pneumatic rotary chuck rear chuck has high precision, stability and easy maintenance, which can help users easily realize efficient and accurate pipe processing.

▎What are the advantages of through-hole pneumatic rotary chuck Rear Chuck ?

1.The inside of the chuck is equipped with a positive pressure dust-proof blowing function, which reduces the occurrence of slider jamming and improves the stability and reliability of the chuck.

2.It has its own through-hole design, which can be connected to an external air blowing and dust-proof system, which can effectively reduce dust accumulation and realize environmental-friendly dust extraction and dust removal.

3.The key parts are heat-treated and precision-grinded, featuring high precision, wear resistance and long life, and the overall precision is superior to other products.

4.The pneumatic rotary chuck rear chuck adopts ground gear, which has high precision and stable running characteristics, ensuring the accurate positioning and reliability of the chuck.

5.The use of well-known brand bearings ensures the high precision and reliability of the rotating parts.

6.It has a wide range of applications, and can clamp different profiles (such as angle iron, channel steel, H-shaped steel, etc.) by replacing the jaws to meet the processing needs of different workpieces.

7.Before the pneumatic rotary chuck rear chuck leaves the factory, it has undergone strict air tightness testing, action trial operation and precision testing to ensure that the product quality and performance meet the standard requirements.

▎After-sales service

24-hour telephone + online after-sales engineer 1 to 1 online technical guidance service, escorting your purchase and use!

Q: What parameters should be provided to get a proper quote?

Answer: Use the model (plate pipe machine or pipe cutting machine), the specification and size of the clamped pipe (such as: round pipe diameter, wall thickness, length, etc.).

Q: Can I visit your company to understand the products before delivery?

Answer: You are welcome to come to Dai Ruike for guidance.

▎Performance parameter

| OD (mm) |

Centre-height (mm) |

Total Weight (Kg) |

Inertia (K g.cm ²) |

Repeatability (mm) |

Rotary precision mm |

| Φ346 | 175±0.05 | 145 | 96000 | ≤0.10 | ≤0.15 |

| Single Claw trip (mm) |

Single Claw thrust (Kg.f) |

Processing Range (mm) |

Permissible pressure (M pa) |

Rated speed (rpm) |

thickness of pipe (mm) |

| 43.3 | 210 | 15-218 | 0.3-0.8 | 150 | ≥1 |

▎Application